Service availability

We have an emergency technical support team to solve the faults that may arise.

Our technicians will go to the site of the fault with the necessary equipment to analyse it, carry out the diagnostis and repair it in the shortest time possible.

If you need a spare part and do not have it, we can supply it from our stock

With the usual spare parts on hand

Our technicians are on the road at all times with the necessary spare parts pto replace any of the components of the equipment that typically experience wear and tear.

We always have pressure switches, solenoid valves, electrodes, ignition cables, gaskets, retaining washers, fuel pumps, seals, etc.

Industrial supplies and spare parts

In order to provide a good Emergency Technical Support Service it is necessary to have spare parts available to repair faults in the shortest time possible

At SERINCAL we have an extensive stock of industrial supplies of the top brands for any type of installation, mainly spare parts for fluid control and elements for boilers and burners

Valves

Safety valves

Safety valves come in a variety of designs, materials and sizes depending on their application. In steam boilers, spring-loaded, instantaneous full opening safety valves are commonly used.

To place the order it will be necessary to know the tare pressure and evacuation capacity.

Pressure-reducing valves

Reduction of steam pressure, gases and neutral liquids in energy networks and processes.

Pressure-reducing valves are poppet valves with compensated inlet and outlet pressure, which work as a proportional controller without auxiliary power.

Steam traps

Also called condensate traps, they remove the liquid phase in steam installations.

Their operation is based on the difference in properties between steam and condensate, as well as on the process for which they are destined. The valve is thus driven through expansion of a small plate in the presence of steam and condensate.

Check valves

This is the simplest and most reliable way to avoid steam and heat transfer fluid returns in installations.

They are composed of a spring and a gate (disc) that return to their position as soon as the flow has stopped.

Bellow valves

These have a bellow seal and are maintenance-free as there is no need to change gussets.

Suitable for steam, gases, hot water, hot fluids, heat transfer fluid, process water, vacuum stations, etc.

Automatic drain valves

Automatic bottom blowdown valve. As the boiler produces steam, the salts dissolved in the water concentrate and precipitate.

It is necessary to remove these salts to avoid corrosion.

Water pumps for steam boilers

Centrifugal pumps

Also called vertical pumps, they are normally used in shell boilers.

These are recommended for almost all conventional boilers, although it is advisable to check the temperature of the feed water and the working conditions of the pumps.

Multicellular pumps

Also called horizontal pumps, these are traditionally used in steam boilers.

They have an electric motor coupled by a plastic link (mechanical fuse) to protect it in case of malfunction or interlocking inside the pump or motor.

Piston water pumps

These are high pressure pumps that make it possible to easily raise the pumping pressure, such as our forced circulation boilers.

Maintenance of these pumps requires the use of oil in the moving parts (red plug) and periodic valve changes.

Water softeners

We have water softeners designed to work in harsh industrial conditions.

Choosing the perfect water softener involves knowing: the cycle or volume of water to be softened, and the flow rate that will pass through it. Mandatory for the maintenance and effectiveness of a steam boiler.

Other common spare parts

Spare parts for burners

The burner is the heart of the boiler, just as a processor is the life of a computer.

All automatic regulation and control elements must be of the highest quality, to avoid surprises in the future. In general, the recommended spare parts for each burner will vary depending on the fuel to be used.

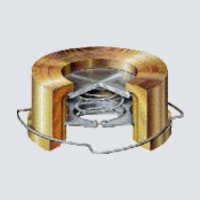

Expansion compensating devices

Installations with long pipe runs are subject to expansion and compression due to the temperature difference between the time of assembly and the working conditions.

Expansion compensating devices ensure the proper operation of the installation and prevent breakage.

Manhole gaskets

Manhole and handhole gaskets are truly special gaskets.

They are specially manufactured and placed in the boiler closures only an operator can access.